ashtrans said:

note the V8 bellhousing will rotate the auto box about 20-25 degrees so ideally you will need the deeper range rover sump but this may reduce ground clearance, what did you guys do about this ?

It's actually only about 10 degrees, Dave. The tilt is towards the pickup, and I used the BMW pan, making sure that it was filled correctly and the dipstick marked accordingly. No further problems, certainly none in use. The LR sump is too low for the P6 - you end up with a smidge over 100mm of ground clearance, and a car that looks like it's pregnant.

As covered in the ZF general discussion thread, I've used the Dakota Digital ECD-100 to drive my speedo - the major advantage is that your stock speedo remains untouched, rather than having to install an aftermarket dial or have its guts removed and replaced with electronics; an option I explored early on but abandoned in favour of the Dakota, which was a doddle to install.

I've also used the stock P6 selector, unmodified, operating the ZF lever by means of a Jag XJ40 cable (eightofthem's tested solution). People mustn't believe the pub stories - all positions are available (PRND321) using the P6 selector. Only cable adjustment is required.

The final solution will vary from car to car, but mine ended up as follows:

- '94 Land Rover Discovery gearbox.

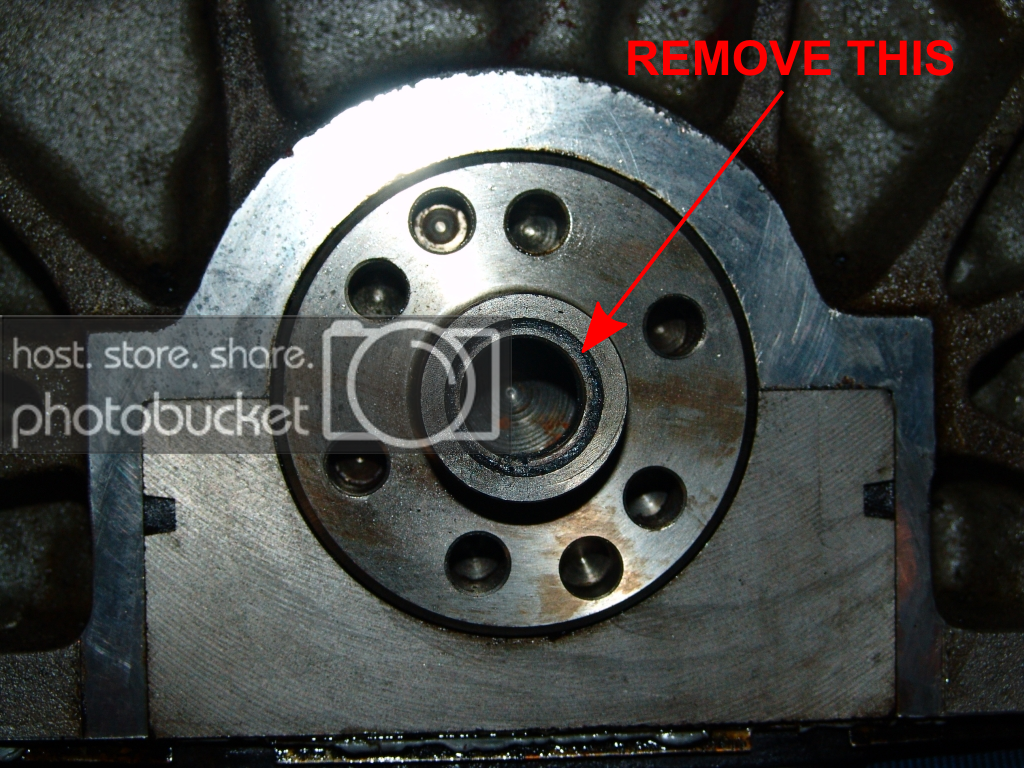

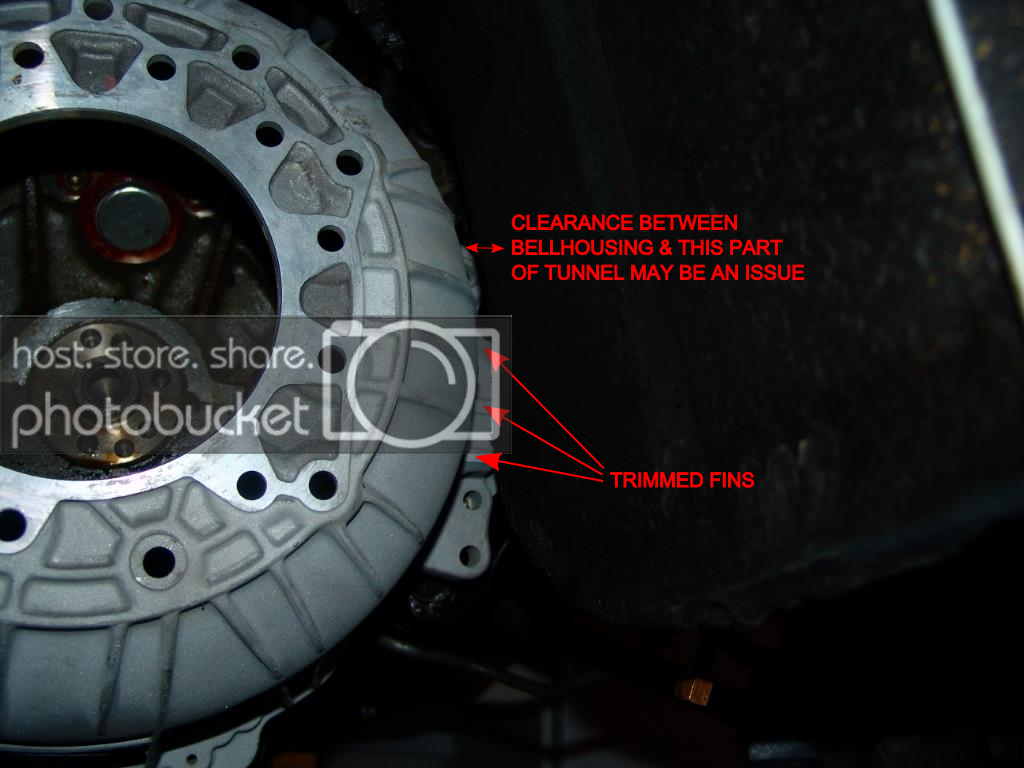

- 'At the front: '94 Discovery bell housing (with three fins ground back for clearance, more on this in the near future) torque converter, spacers, crank adapter and flex plate.

- Stock P6 starter motor. The LR ring gear, if not the flex plate itself, is identical to the P6B item, so the P6B starter motor remained untouched during the conversion.

- At the rear: BMW tail housing, output shaft and parking pawl/gear; and a custom-made crossmember that bolted to the existing P6 transmission tunnel brackets. No welding of the car required.

- Land Rover governor and valve body.

- BMW sump and filter.

- Jaguar XJ40 output yoke/flange. Required a few millimetres milled off the leading edge of the shaft to make it sit properly in the BMW rear seal, but it mates exactly to the P6 propshaft.

- Totally unmodified P6B propshaft. Just bolted it back in where it used to go. This may not be the case if you use a Jag rear end, and almost certainly won't be if you use the Sherpa/LDV box.

- Stock P6B selector operating the ZF via a Jaguar XJ40 cable (more on this in the near future).

- A hybrid TV/kickdown cable, made from the existing P6B cable with LR/BMW fittings grafted on to the gearbox end. Cost me $20 to have it made from my existing parts.

- A filler/dipstick tube made from the LR item and some flexible hose. I reused the LR dipstick (cut down a little) but plan to modify the BW35 dipstick since it's a much classier item. Fits in the top but needs to be shortened.

- Dakota Digital ECD-100 speedo converter (as described above).

- Custom cooling lines utilising the LR fittings and shaped to meet up with the existing cooling lines running along the side of the engine block.

- A dedicated transmission cooler. Needed! The first longish run showed that the piggy tail in the P6B radiator just wasn't going to cut the mustard.

I did almost all the work myself, but it was hard going at times for somebody who'd never peeked inside an auto transmission before. It will be very good if those looking for an easier path can purchase what amounts to a kit. I can't recommend the ZF enough. The smoothness alone is quite remarkable after the BW, but the overdriven top gear and lockup torque converter have totally transformed the car. I hope a few Forumites more take the plunge - so far I'm the only confirmed completion. We have one underway (Geordie Jim) and an estate that has been fitted with a 3.9 EFI/ZF combo at some point way back in the dim darks but appears to have been languishing just short of completion (although its future is now looking brighter).